Electrical Safety Audit

An Electrical Safety Audit is a systematic examination of an organization's electrical systems, equipment, and practices to ensure compliance with safety standards, identify potential hazards, and recommend corrective actions to prevent accidents, injuries, or equipment damage. It is a critical component of any workplace safety.

-

For queries, & Assistance

What is Electrical Safety Audit?

An Electrical Safety Audit is a systematic examination of an organization's electrical systems, equipment, and practices to ensure compliance with safety standards, identify potential hazards, and recommend corrective actions to prevent accidents, injuries, or equipment damage. It is a critical component of any workplace safety.

Why your Organization would require Electrical Safety Audit?

Organizations would require Electrical Safety Audit site inspection in order to attain the below benefits:

- Prevent Electrical Accidents

- Ensure Compliance with Regulations

- Reduce Downtime and Equipment Failures

- Protect Employees and Contractors

- Minimize Fire Risks

- Improve Energy Efficiency

- Extend Equipment Lifespan

- Reduce Insurance Premiums

- Prepare for External Inspections

- Identify and Address Hidden Hazards

- Documentation and Record-Keeping

- Protect Your Reputation

- Cost Savings

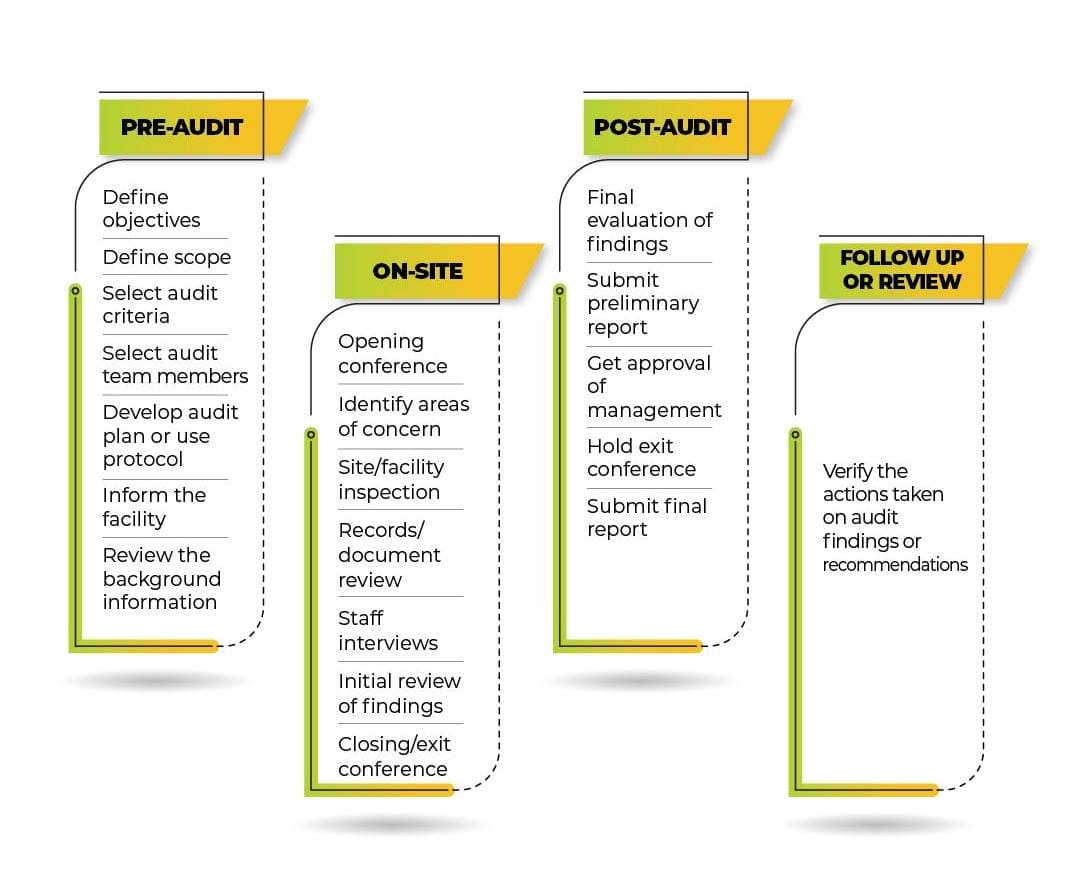

What are the various steps involved in the Electrical Safety Audit process?

- Opening Meeting with the client team

- On-Site Inspection

- Data Collection & Reviewing the documentation

- Closing Meeting with the client team

Why choose NIST for Electrical Safety Audit?

Industry Experience

o With more than 15 years of experience in safety services, NIST Global has successfully conducted electrical safety audits for leading companies.

Proven Expertise:

Deep understanding of national safety standards (CEA Regulations, BIS Standards, NBC Guidelines).

Support

(Pre-audit, On-site & Post-audit)

An Excellent end to end support to clients during

Customized Solutions:

- Tailored audits to meet the unique needs of your industry and facility.

Advanced Tools and Techniques:

- Use of cutting-edge technology like thermal imaging, earth resistance tests, insulation testers, and arc flash analysis.

Comprehensive Reporting:

- Detailed reports with actionable recommendations to mitigate risks and ensure compliance

Experienced Team:

- Certified electrical engineers and safety professionals with extensive field experience.

Client-Centric Approach:

- Focus on building long-term relationships by delivering value and ensuring client satisfaction.

Our Audit Process

- Planning and Preparation:Define scope, gather documentation, and develop a customized audit plan.

- On-Site Inspection:Thorough visual inspection and advanced testing of electrical systems and equipment.

- Risk Assessment:Identify hazards, evaluate risks, and prioritize corrective actions.

- Compliance Check: Ensure adherence to regulatory standards and best practices.

- Detailed Reporting: Provide clear, actionable insights with recommendations for improvement.

- Follow-Up and Support: Provide clarity in implementing corrective actions and conduct follow-up audits.

What your organization will receive from our Electrical Safety Audit service?

Provision of expert support and advice which can include:

- Executive Summary Report for the Management

- Customized Electrical safety audit checklist with respect to client’s business model

- Detailed analysis of Observations and its Recommendations

- Pictorial evidence supporting observations

- Detailed dashboard tracker for multi-location audit

What are the parameters covered in Electrical Safety Audit?

Electrical Panels and Distribution Boards

- Condition of panels

- Labelling

- Accessibility

- Overloading

Wiring and Cables

- Insulation

- Routing

- Grounding

- Load balancing

Protective Devices

- Circuit breakers and fuses

- Residual Current Devices (RCDs)

- Earth leakage protection

Electrical Equipment and Appliances

- Condition

- Certification

- Portable appliance testing (PAT)

Earthing and Bonding

- Earthing system

- Bonding conductors

Lighting Systems

- Fixtures

- Emergency lighting

- Exit signs

Switchgear and Control Gear

- Condition

- Operation

- Interlocks

Hazardous Areas

- Classification

- Equipment suitability

- Explosion protection

Work Practices and Procedures

- Lockout/Tagout (LOTO)

- Permit-to-work systems

- Training

Environmental Factors

- Moisture and dust

- Temperature

- Ventilation

Emergency Preparedness

- Fire extinguishers

- First aid kits

- Emergency procedures

Compliance with Standards and Regulations

- Local regulations

- International standards

Risk Assessment

- Hazard identification

- Risk evaluation

- Control measures

Transformers

- Physical condition

- Cleanliness

- Ventilation

- Oil level

- Oil quality

- Radiators and fans

- Cooling oil pumps

- Temperature indicators

- Buchholz relay

- Pressure relief device

- Overcurrent and overload protection

- Surge arresters

Review and Reporting

- Audit findings

- Recommendations

- Follow-up